Research Progress in the US – The Flexible Electronics Market Burst out

How many sensors are there on our body to make us feel healthy? To answer this question, you must know about the flexible hybrid electronics - a unique industrial technology research direction.

Flexible hybrid electronics (FHE) is considered as the future of the electronics industry and it has become an important research topic for the government of the United States (US) due to its wearability, bendability and stretchability. In particular, the US military invested heavily in the development of flexible electronics, which shows the strategic significance of this technology in the future.

清华大学航天航空学院的冯雪教授和浙江大学化学工程与生物工程学院的谢涛教授团队合作,In August 2015, the 7th manufacturing innovation institute in the US - Flexible Hybrid Electronics Manufacturing Innovation Institute, was established in the Silicon Valley. This institute is led by the Department of Defense with a total investment of US$171M, of which US$75 million comes from federal funding and US$96 million is non-federal funding. The FlexTech Alliance will lead 96 companies, 41 universities, a group of 14 state and local government organizations, 11 laboratories, and non-for-profit organizations to ensure the US is leading the next generation of flexible and wearable electronic device manufacturing. This group consists of the main American electronics and semiconductor companies such as the applied materials companies, Apple and the United Technologies Corporation as well as leading research institutes like Stanford University, Harvard University and Massachusetts Institute of Technology. The new institute will focus on the leading research of flexible hybrid electronics production to form wearable and stretchable silicon circuits and sensors via high-performance appliances and printing technologies.

Applications of FHE include the following:

1.monitor vital signs and physical status through wearable electronic information devices to optimize health and lifestyle decisions;

2.significantly improve the delivery of medical technologies through biomarkers and implants to monitor the vital signs of patients with chronic diseases and combat soldiers;

3.monitor the operating status of car and airplane under severe weather conditions through the embedded sensor;

4.enhance the security of military operations by applying lightweight robots and next-generation imaging and sensor capabilities to a variety of land-based, sea-based, space-based, and space-based systems;

5.significantly reduce the size and weight of electronic system modules by fitting them into the shape of aircraft and other vehicle platforms, or by integrating them into clothing and fabrics.

NextFlex is worth of paying attention to among the American innovation institutes, as its research directions and industrial applications are highly related to everyone’s daily life, which includes the wearable applications of health monitoring devices, the sensor of the Internet of Things, and the integrated application of array antenna. Big technologies firms such as Huawei and Xiaomi are paying close attention to the smart wear technologies such as smart wristbands as it is a fast-growing industry. Of course, the sort of smart watch you are using now is nothing compared to NextFlex. NextFlex demonstrates enormous market value and a bright future.

The flexible sword

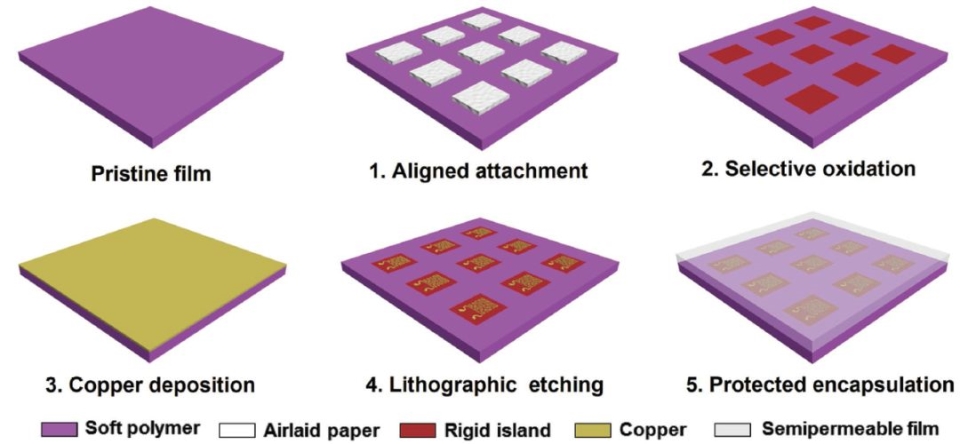

You need to learn about Flexible Hybrid Electronics (FHE) before understanding how NextFlex works. Quite different from the traditional chemical etching methods, FHE creates printed circuit boards on flexible materials to realize folding and flexible bending for electronic equipment. ,该方法预先编程控制衬底的刚度,得到刚性区域与柔性区域相间分布的衬底,然后直接在衬底表面进行薄膜沉积与光刻等操作。其中,功能微单元位于刚性区域,在应变隔离的环境中稳定工作,而柔性区域则负责连接各功能微单元,使器件整体柔性可拉伸。

刚度可编程衬底

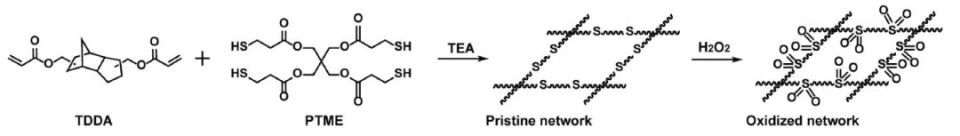

该功能衬底为通过硫醇-丙烯酸酯点击化学反应合成的聚硫化合物薄膜,被过氧化氢氧化后转变为聚砜化合物。为了实现特定区域的氧化,研究者使用图形化的无尘纸作为载体吸收过氧化氢水溶液(30%)覆盖于薄膜表面来完成氧化,区域氧化后薄膜的弹性模量提高了150倍。

材料的合成

基于刚度可编程衬底的柔性电子器件制备流程

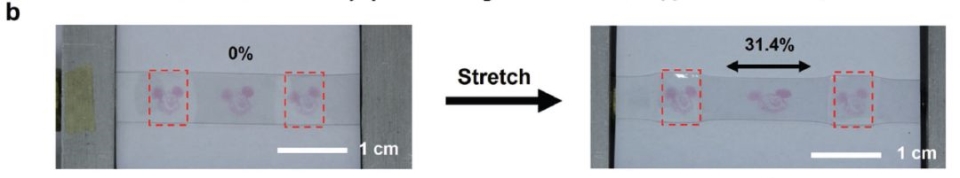

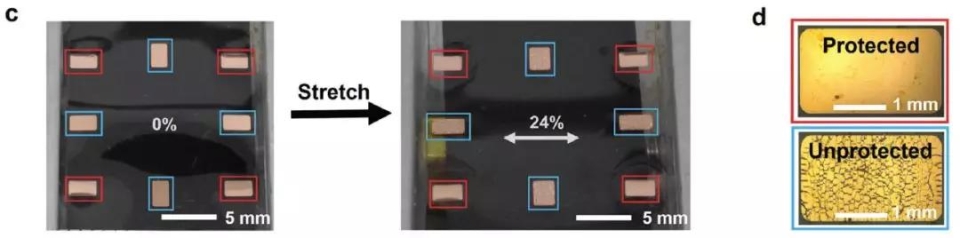

衬底在经受拉伸时,由于弹性模量的巨大差别,未氧化区域即柔性区域被拉伸,而被氧化的部分即刚性区域的应变则几乎为0。

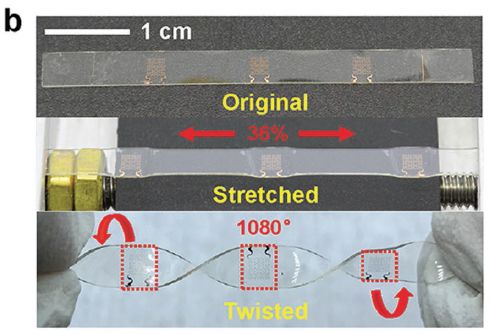

图b 印有米奇图案的刚度编程衬底拉伸前后对比 图c, d 沉积金属薄膜的刚度编程衬底拉伸前后对比

图b 印有米奇图案的刚度编程衬底拉伸前后对比 图c, d 沉积金属薄膜的刚度编程衬底拉伸前后对比

高性能可拉伸温度传感器

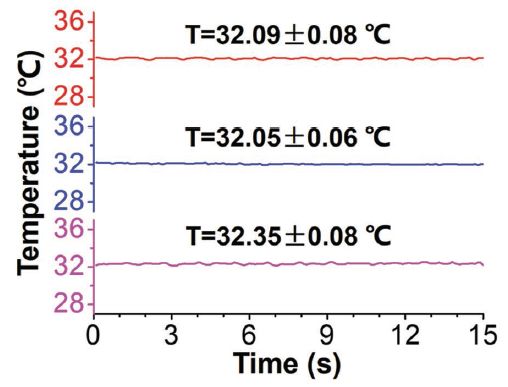

金属电阻式温度传感器具有精度高、响应快、分辨率高等优点,但对于柔性可拉伸温度传感器,应变同样会引起电阻的相对变化,进而影响温度测量的结果。利用基于刚度可编程衬底的柔性电子制造方法,可以将应变敏感的温度传感微单元布置于刚性区域,从而完美解决热阻效应与压阻效应耦合的难题。

图b 可拉伸温度传感器阵列

研究者们展示了可拉伸温度传感阵列在动态力学环境下的测温实验,实时监测手腕关节与膝关节在持续运动状态下的温度。

手腕运动状态下温度的实时测量

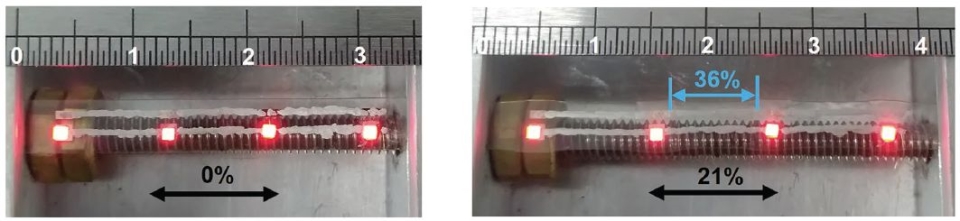

此外,研究者们还展示了柔性可拉伸LED灯链,减薄的LED芯片(15μm)位于刚性区域,当器件承受拉伸时,柔性区域的导电银胶导线随之变形。

柔性LED灯链拉伸前后的对比

柔性LED灯链拉伸前后的对比

基于刚度可编程衬底的制造方法与现有光刻制备工艺兼容,制备过程无需转印,极大降低了柔性电子器件制造的复杂度,是一种适用于柔性电子商业化生产的有效方法。

参考文献:

Y. Cao, G. Zhang, Y. Zhang, M. Yue, Y. Chen, S. Cai, T. Xie, X. Feng, Adv. Funct. Mater. 2018, 1804604.